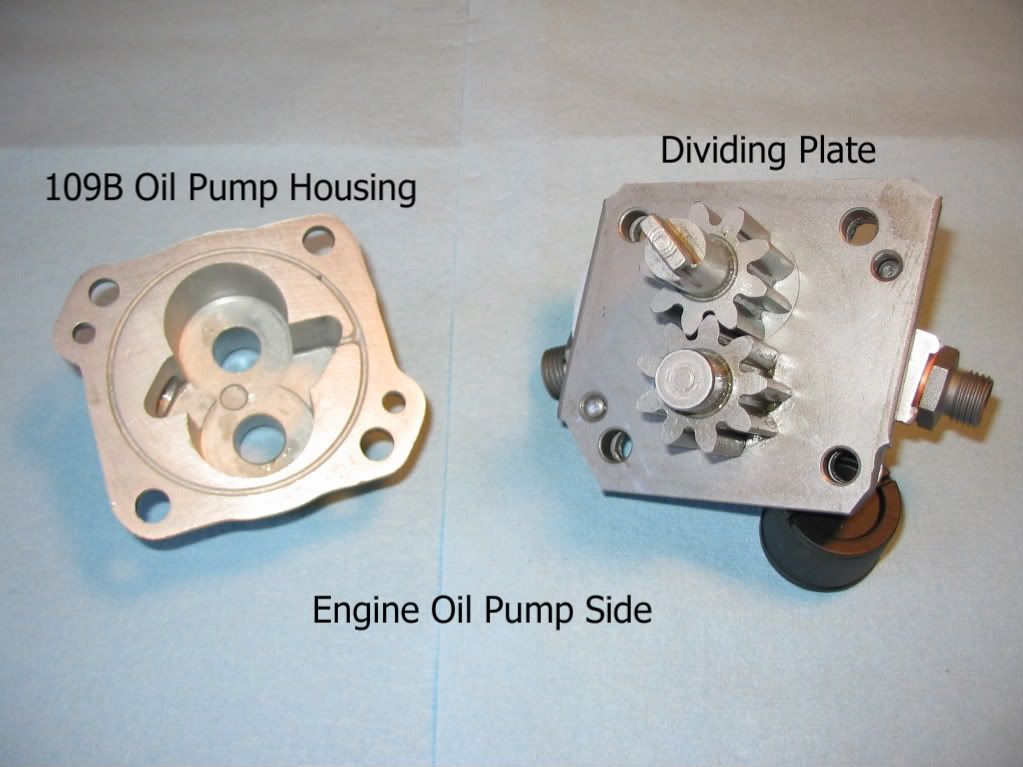

Barnes Oil Pump Disassembly

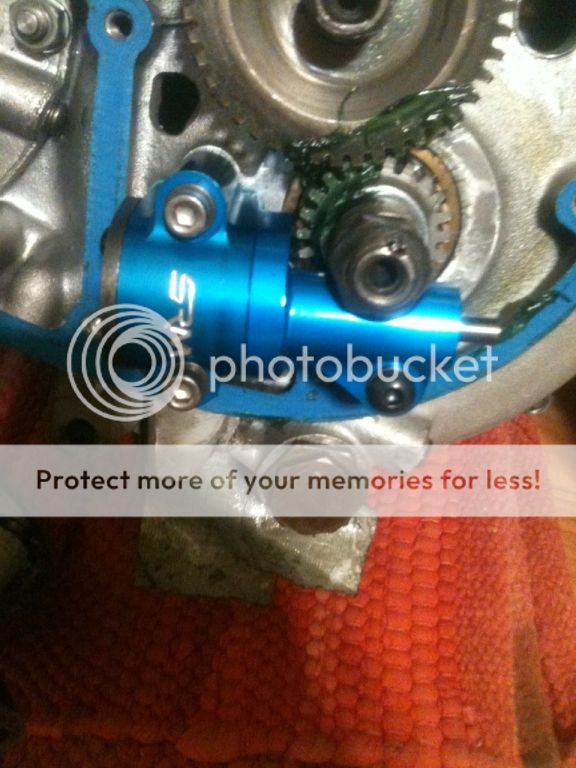

Oil pump disassembly these are a second oil pump that continues to run after the engine has stopped providing cooling oil to the hot bearings of a turbocharger for some minutes whilst it cools.

Barnes oil pump disassembly. Remove the oil pump. Read all instructions in this manual before operating pump. Use tooling a to remove the shaft. If the pump is idle for long periods of time it is advisable to start the pump occasionally by adding water to the basin.

Before removing the pump from the basin be sure to close the shut off valve. 420 third street 83 west drive bramton piqua ohio 45356 ontario canada l6t 2j6 phone. This prevents backfl ow from the pressure sewer keep the control panel locked or confi ned to prevent unauthorized access to it. 9017 sprint car pumps.

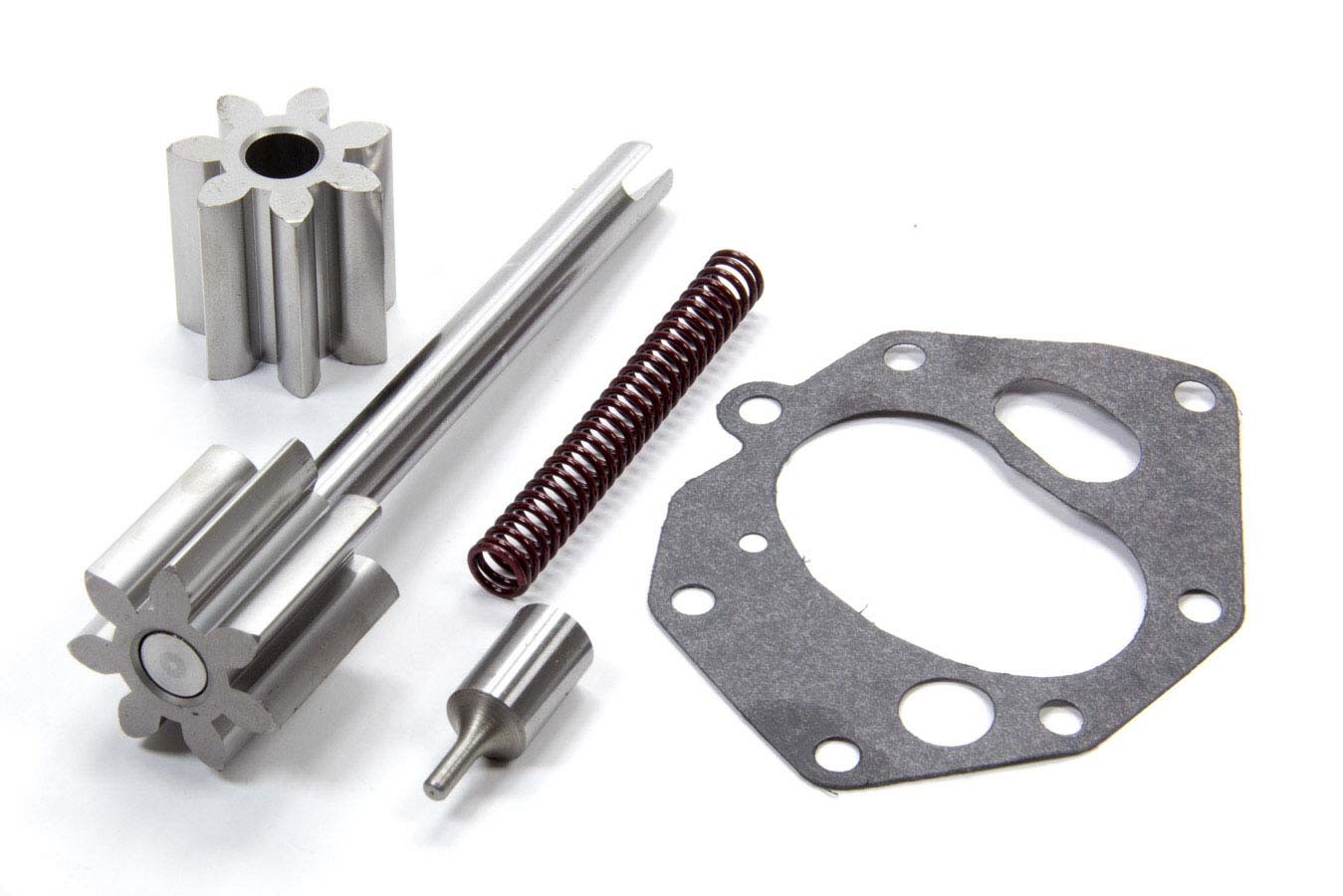

Page 1 barnes barnes service manual ogp 2 hp pump important. Remove the spring and the bypass valve. The pump is removed and the drive motor with its blower wheel shown. A comprehensive video of disassembly cleaning and reassembly of a xl buell oil pump.

As a result of crane pumps systems inc constant product improvement program product changes may occur. As such crane pumps systems reserves the right to change product without prior written notifi. Oil pump disassembly for reliability it is rare to use an external drive mechanism either a separate belt drive or external gears although camshaft driven pumps often rely on the same timing belt. Sgv 2hp disassembly visual inspection of pump quick visual inspections can save time.

9025 drag race pumps. A visual examination of the pump for damage to cords controls or cutter and a thorough electrical check should be performed to determine a pumps condition. Read all instructions in this manual before operating pump. Plus an overview of the current updates of the oil pump.

Remove the bolt that holds drive gear 1 on the shaft. For quality oil pumps accessories oil system service and repair barnes system inc is here for you. As such crane pumps systems reserves the right to change product without prior written notifi cation. As a result of crane pumps systems inc constant product improvement program product changes may occur.

Remove the key from the shaft. Put alignment marks on the pump in order to assemble the gear and the shaft properly. Remove retainer 3 from the bypass valve. Cut cords check the cord s for any cuts or gouges.

9017 dirt late model. 9117 sprint car pumps. A short display of the oil gun burner with disassembly into its component parts.